Provide intelligent factory automation solutions

Smart Factory | Intelligent Warehouse | Intelligent Production Line

Automated Storage and Retrieval System (ASRS)

Realize digital management, real time monitoring and control of inventory

Factory Production Line Smart Automation

Reduce dependence on employee experience, information system monitoring and control based on set parameters

Full Space Unmanned Intelligent Transport Equipment

Reduce number of SKU in storage, increase warehouse efficiency

Factory Custom Automation Equipment

Decrease number of skilled personnel required, Increase task accuracy and precision

Core Products

We have 20 years of experience in research and development,We have highly skilled teams with rich technical experiences in the field of storage and production line automation.

Our products consist of Automated Storage and Retrieval System (AS/RS), Production line automation, Unmanned Material Handling equipment (AGV/AMR/OHT/OHS etc), Custom automation machinery, and System control software.

Our products are currently deployed in these sectors: Logistics, New Energy, LCD, Home electronics, Furniture, Food and beverage, Electrical, Hydraulic etc.

Mutual Achievement, Mutual Progress

For employee’s happiness, For the company’s benefit, For society’s progress!

Our Portfolio

Korea: world top 10 New energy company smart conveyor system

China large scale pet food company smart conveyor system

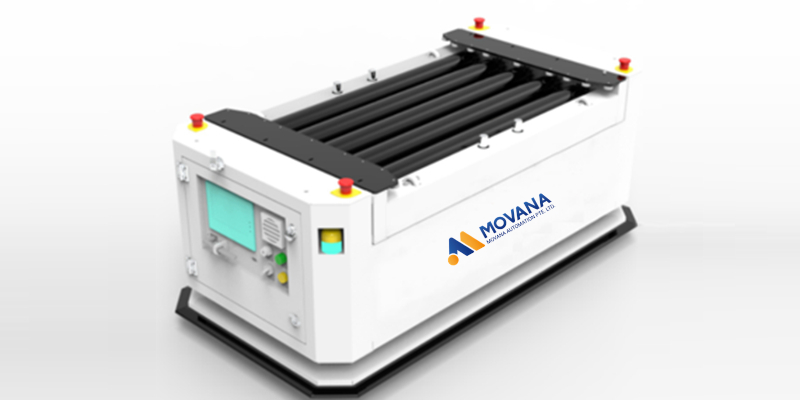

Korea: world top 10 new energy company Roller AVG

Korea: world top 10 new energy company twin roller lifter AGV

Korea: world top 10 new energy automatic pallet depalletizing/palletizing equipment

Partnering Customers

We provide R&D, production, and support services in the field of factory automation to LG group of companies, LG energy solution, LG Chem, LG Display, LG Electronics, and international companies like Skyworth and China Pet Foods.

Partnering Brands

To ensure our customer’s equipment have the highest quality, capability, and reliability, our products and designed and made with the best parts available in the market.